|

Maxisafe |

|---|

|

MAXISAFE HARNESSES AND THE IMPORTANCE OF TESTING Working at height carries a number of responsibilities. Responsibilities for users and manufacturers alike - none of these responsibilities surpass that of testing/inspection for without it all that follows is meaningless. At the core of Height Safety, the way our body is protected stands out when all else functions properly. Maxisafe has this front of mind when harnesses are considered. Successful testing and ongoing acceptable inspection are the two keys to this. Firstly, compliance with the Australia / New Zealand Standard 1891.1:2020 provides the yardsticks for harness safety. Maxisafe ensures that within this testing regime and comfort trials that follow all bases are covered. All materials used within the harness have yardsticks – even the thread should be manufactured from high tenacity fibre and have melting point and chemical resistance equivalent to or greater than that of the webbing being sewn. Lives are safe when hanging by this thread. Webbing is to be high tenacity fibre to meet size requirements, strength and even capable of satisfying strength tests after being subjected to controlled dose (equivalent to 10000 hours) of our great sunlight – we all know the damage UV light can do to not only ourselves but the fabric we wear. Hardware used in harness receives the same attention. Simplicity to connect but great locking retention is key to buckles and adjusters. The ability to sustain loads applied to them during a fall is essential for Maxisafe harnesses. Buckles and Adjusters alike are tested to safely accommodate loads in a fall scenario. Specifically, adjusters/buckles are subjected to corrosion resistance (harnesses can have up to a ten-year life) – protection against deterioration due to corrosion is tested. |

|

|

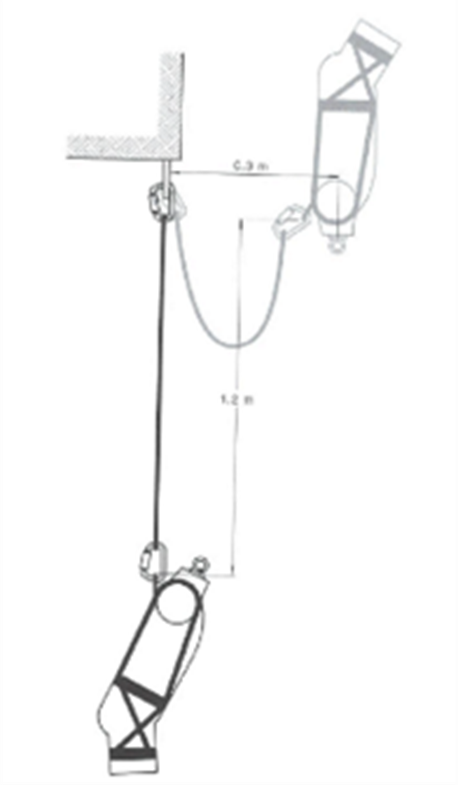

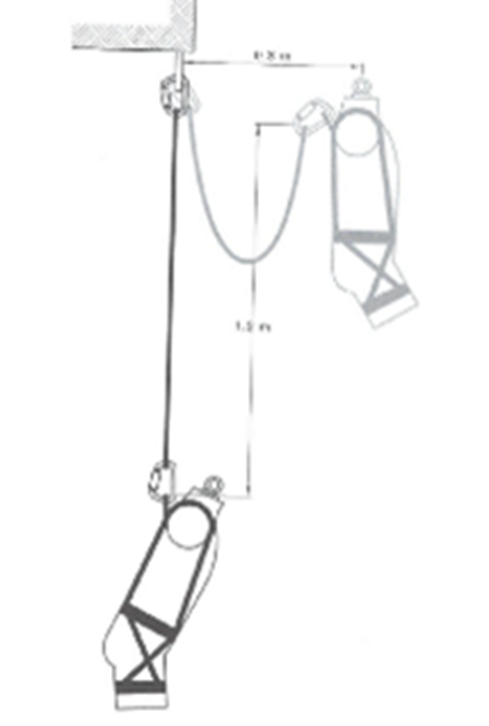

The harness yardsticks require fall arrest harnesses, once fitted to a standard rigid manikin, to be tested by subjecting them to freefalls in both heads up and heads down orientation. Testing is conducted on a solid, stainless steel lanyard without any means of absorbing the energy of the fall (in the order of 12kNm or Joules). Users of harnesses of these designs successfully tested of course use lanyards with shock absorbing mechanisms that will place no more than 6kN force on their body (testing of Shock Absorbing Lanyards and Inertia Reels is a topic for further review just as important). |

|

Forces on the human body are important in that significant internal organ damage can occur if human body is subjected to fall forces of around 12kN or greater – the spleen is noteworthy here as it may detach when subjected to such forces. This harness testing guarantees users of Maxisafe harnesses and lanyards that they can not only easily don them with confidence, but they will be well protected by them in the event of a fall. When followed, the fitting instructions provide correct fit. It is important to understand that when harnesses are tested, they are properly fitted. The sub pelvic strap should be in tension to maximise its effectiveness. Users should ensure this for their ongoing safety. As a result, in the event of a fall and thereafter loads are distributed to the parts of the body which can sustain them – thighs and buttocks. |

Secondly users should not only consider the protection offered by Maxisafe harnesses in the event of a fall but think about the ease of donning, comfort of wearing and importantly how the harness will keep them after such a fall.

After a fall danger still exists. There is the strong possibility that the user may be subjected to suspension intolerance (suspension trauma) caused by the pooling of blood in the legs of the user. This pooling can lead to unconsciousness, heart problems and death. Maxisafe provide, other than the instruction that user should undertake violent movement of legs to return blood to upper body and heart, Suspension Trauma Loops to be fitted to Fall Arrest Harness for such occasions.

Simplicity of fitting, ease of deployment and proper functionality are all tested to ensure Suspension Trauma Straps are fit for purpose.

To enable your harness to fulfill its 10 years of service not only should it have been subjected to the testing regimes outlined earlier you and your Height Safety Inspector are responsible for its ongoing life and you both should be accredited for your part – tested as user and HSI.

Whilst AS/NZS1891.4:2009 is not a testing standard it is widely and highly regarded for what it specifies and recommends on the selection, safe use, and maintenance of fall arrest systems (Harnesses included). Clearly upon reading this standard there is a responsibility placed upon all users/owners of Harnesses – one which translates into knowledge on the use AND care of harnesses. Maxisafe strongly recommends all users undergo the Working at Height training as set out in Appendix E of this standard. Five groups are identified and each one has a competency based accreditation – testing.

As a “Height Safety Operator” or user this standard provides guidance on which Harness to use, what makes it special or fit for purpose, how to don, care for it and in combination with what other equipment it should be used is provided. Registered Training Organisations have taken this and come up with the competency based training.

Having undergone accredited Height Safety/Confined Space/Abseiling training your pre use check of harness is vital – just as the full inspection undertaken by accredited Height Safety Inspector constitutes a test biannually – done to facilitate ongoing safe use of the equipment (in this case Harness).

It is not only the extensive compliance testing of harnesses but that of all associated equipment and accessories, the Height Safety Inspector in providing ongoing support and you the user checking your equipment which ultimately delivers a Maxisafe Harness to be used with confidence and encourages other users to wear them when working at height.

(Diagrams Courtesy of AS/NZS1891.1:2020 and Maxisafe Height Safety Catalogue)

Maxisafe acknowledges the Traditional Owners of the land where we work and live. We pay our respects to Elders past, present and emerging. We celebrate the stories, culture and traditions of Aboriginal and Torres Strait Islanders of all communities who also work and live on this land.